Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

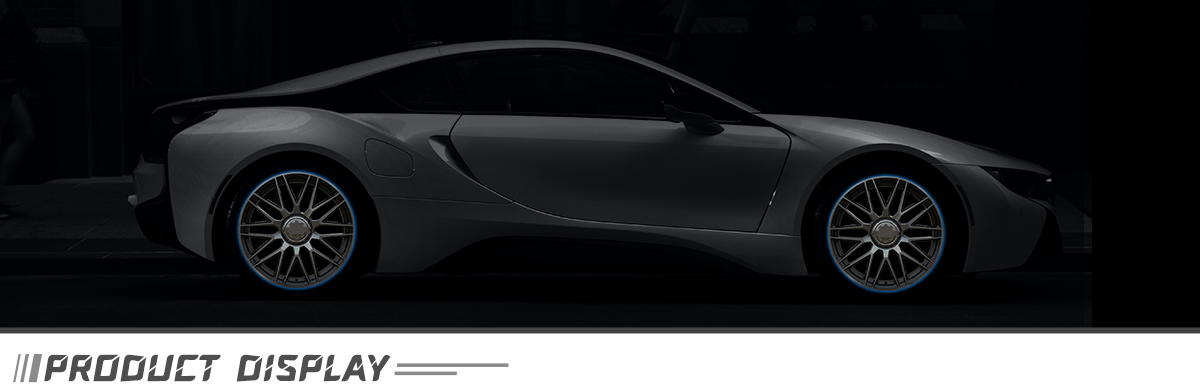

19 inch Replica Car alloy wheels for 2022 new LEXUS Traverse

This 19-inch replica car alloy wheel is the perfect complement to your vehicle. Featuring a modern, stylish design and high-quality materials, these replica wheels are ideal for everyday driving

FITMENT SIZE ET PCD CB

LEXUS 1980 30-35 5*120 60.1

This 19-inch replica car alloy wheel is the perfect complement to your vehicle. Featuring a modern, stylish design and high-quality materials, these replica wheels are ideal for everyday driving. They offer enhanced performance and style at an affordable price. We guarantee 100% customer satisfaction on every purchase with our 1-year quality warranty included in the price.

Features

The 19-inch alloy wheels of the replica car use high-quality alloy materials to achieve both lightness and durability. Featuring a stylish, modern, and unique design, you can customize your car to your liking. Alloy wheels are also corrosion-resistant and will last for years.

Advantages

19-inch alloy wheels on replica cars have many advantages over traditional steel wheels. They are lightweight. This means less overall vehicle weight and better performance. It also improves handling and braking for better cornering and acceleration. Alloy wheels better protect your car's suspension because they absorb bumps and dents better.

Benefits

19-inch alloy wheels for replica cars offer many benefits for your vehicle. They enhance the look of your car and make it stand out from the crowd. It also improves the performance of your car and its handling and braking. Alloy wheels provide better protection for your vehicle's suspension and reduce the risk of damage from bumps and dents.

The process specifications of low pressure casting include pre-pressing, filling, pressurization, saturated pressure, mold preheating temperature, pouring temperature, and mold coating.

Preload and preload speed

Preload pressure refers to the pressure required when the metal liquid level rises to the gate. The rising speed of the molten metal in the riser should be as fast as possible, and it is also necessary to prevent the molten metal from splashing when it enters the gate.

Filling pressure and filling speed

Filling pressure refers to the pressure required to make the molten metal fill up to the top of the mold. In the filling stage, the pressure increase speed on the metal liquid surface is the filling speed.

Boost and boost speed

After the molten metal fills the cavity, pressurization is continued to make the crystallization and solidification of the casting proceed under a certain pressure. The pressure at this time is called crystallization pressure. The greater the crystallization pressure, the better the feeding effect, and the denser the final casting structure. However, increasing the pressure through crystallization to improve the quality of castings cannot be used in all cases.

Holding time

After the cavity pressure is increased to the crystallization pressure, the time required to maintain the crystallization pressure for a period of time until the casting is completely solidified is called the holding time. If the pressure holding time is not enough, the casting will be released before it is completely solidified, and the molten metal in the cavity will flow back to the batch in whole or in part, causing the casting to be "emptied" and scrapped: if the pressure holding time is too long, the gate remains too long, which not only reduces the yield of the process, but also causes the gate to "freeze" (block the gate), making it difficult to mold the casting, so an appropriate pressure holding time must be selected in production.

Mold temperature and pouring temperature

The low pressure casting of automobile aluminum alloy wheels has certain requirements on the working temperature of the metal mold. The working temperature of the metal mold is generally controlled at 350-500C, and when casting thin-walled complex parts, it can be as high as 400-520C.

Regarding the use temperature of low-pressure casting aluminum liquid for automobile aluminum alloy wheels, practice has proved that under the premise of ensuring the forming of castings, the lower the better.